Business Goal

The primary business goal of the company is innovative development and production of aircraft components made of polymer composite materials. Since its inception, the company’s scientific potential has been used in the MC-21 new short-medium-range passenger aircraft project: the young team became one of the project participants as the manufacturer of a composite wing for jet airliner.

Production Capacity

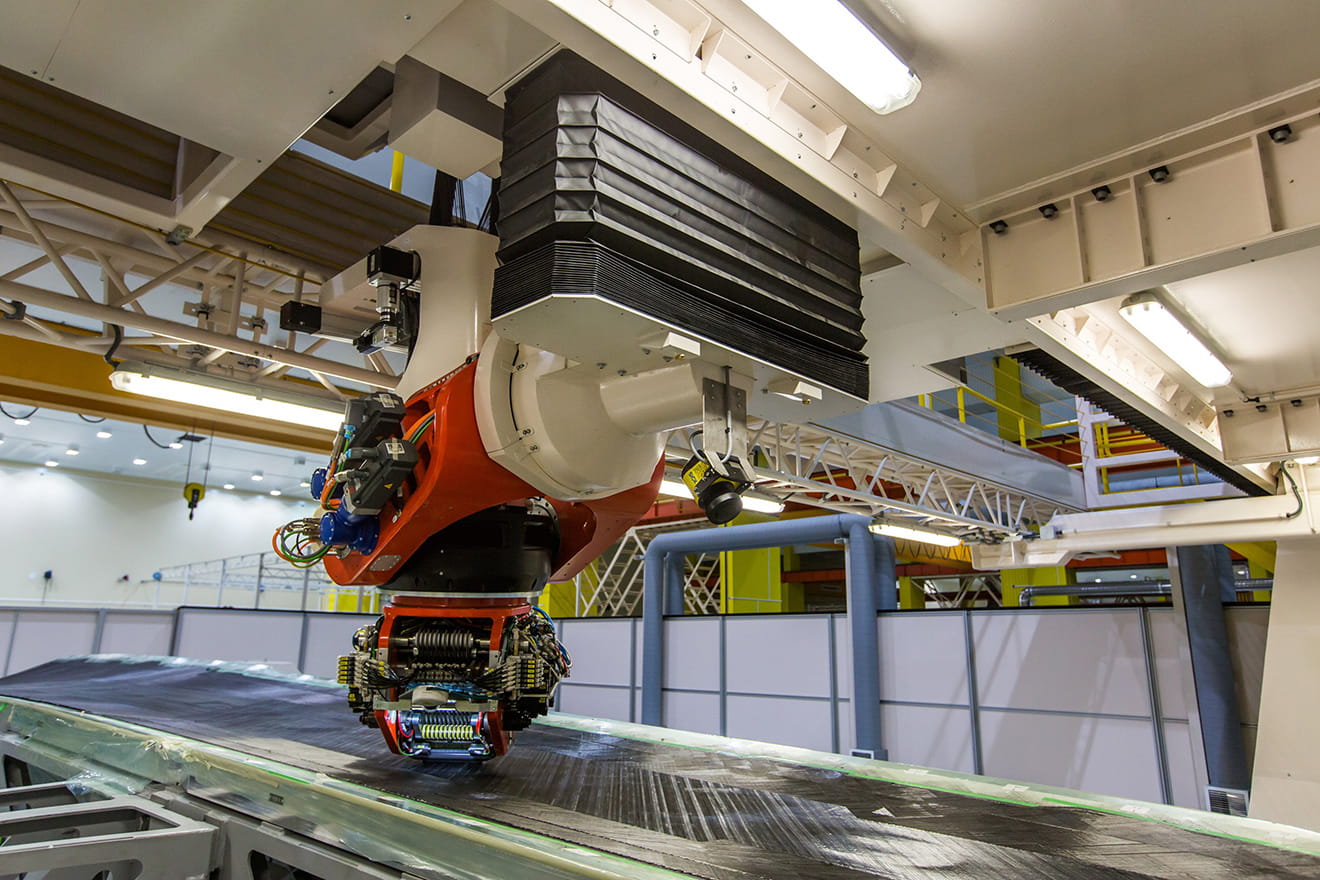

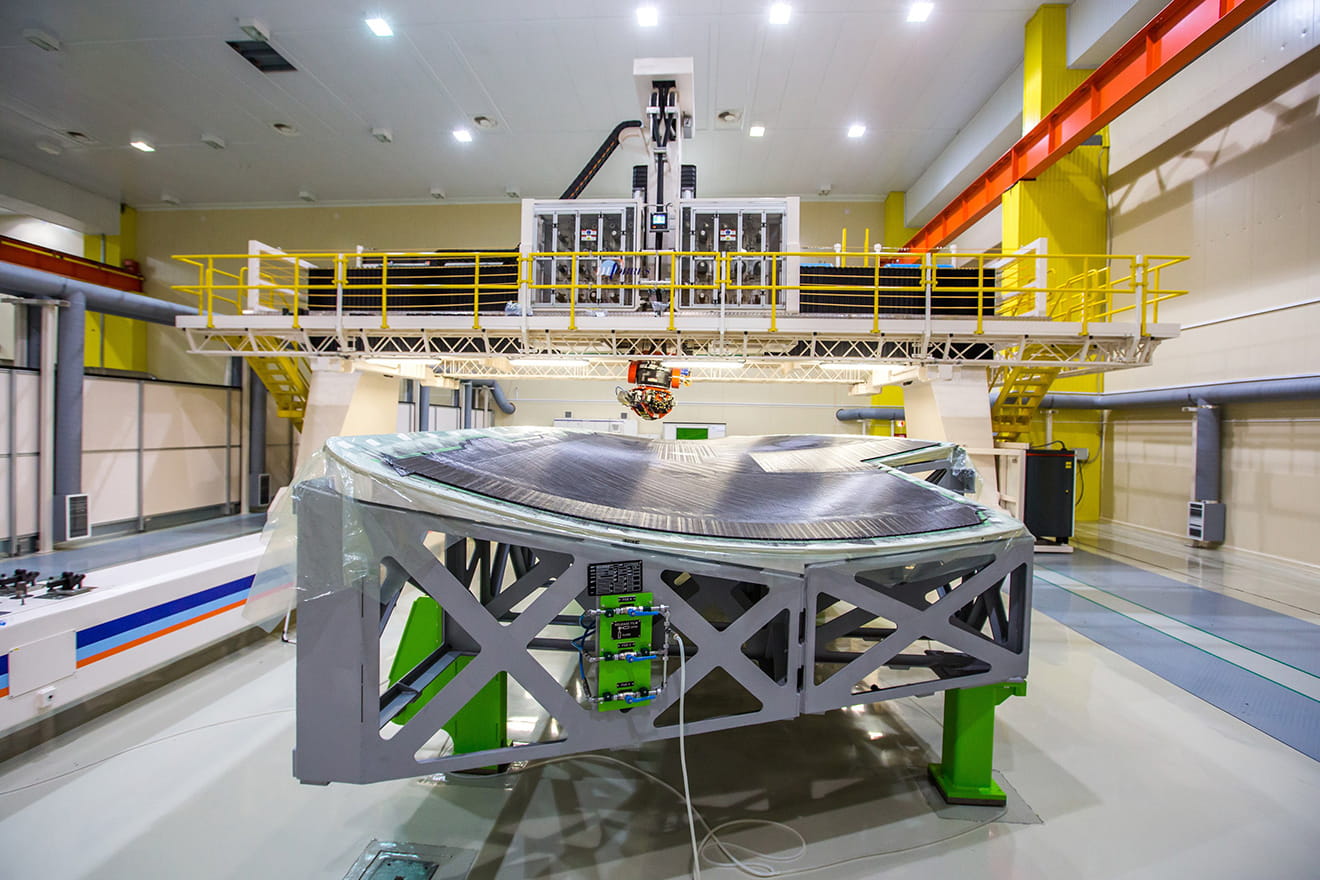

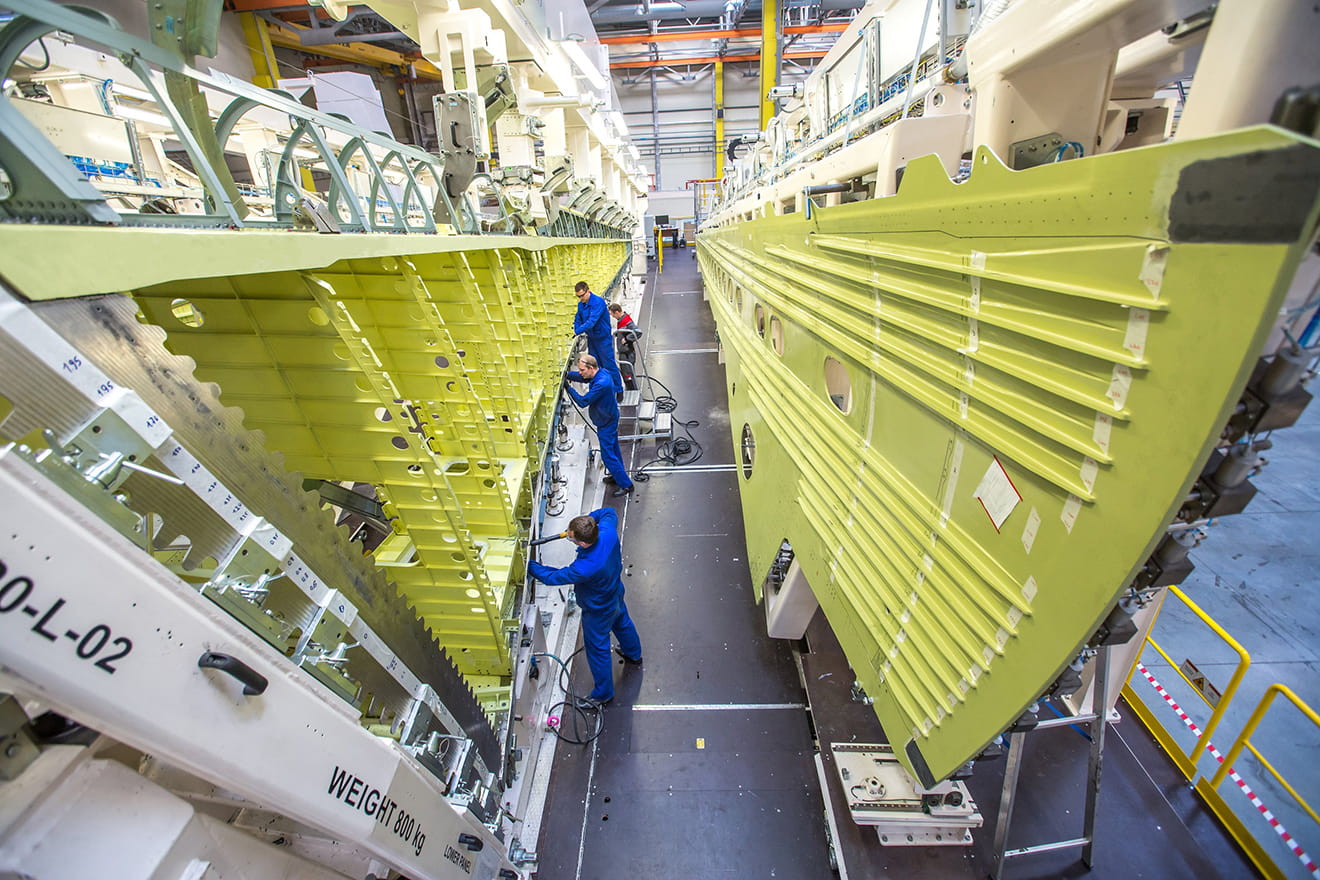

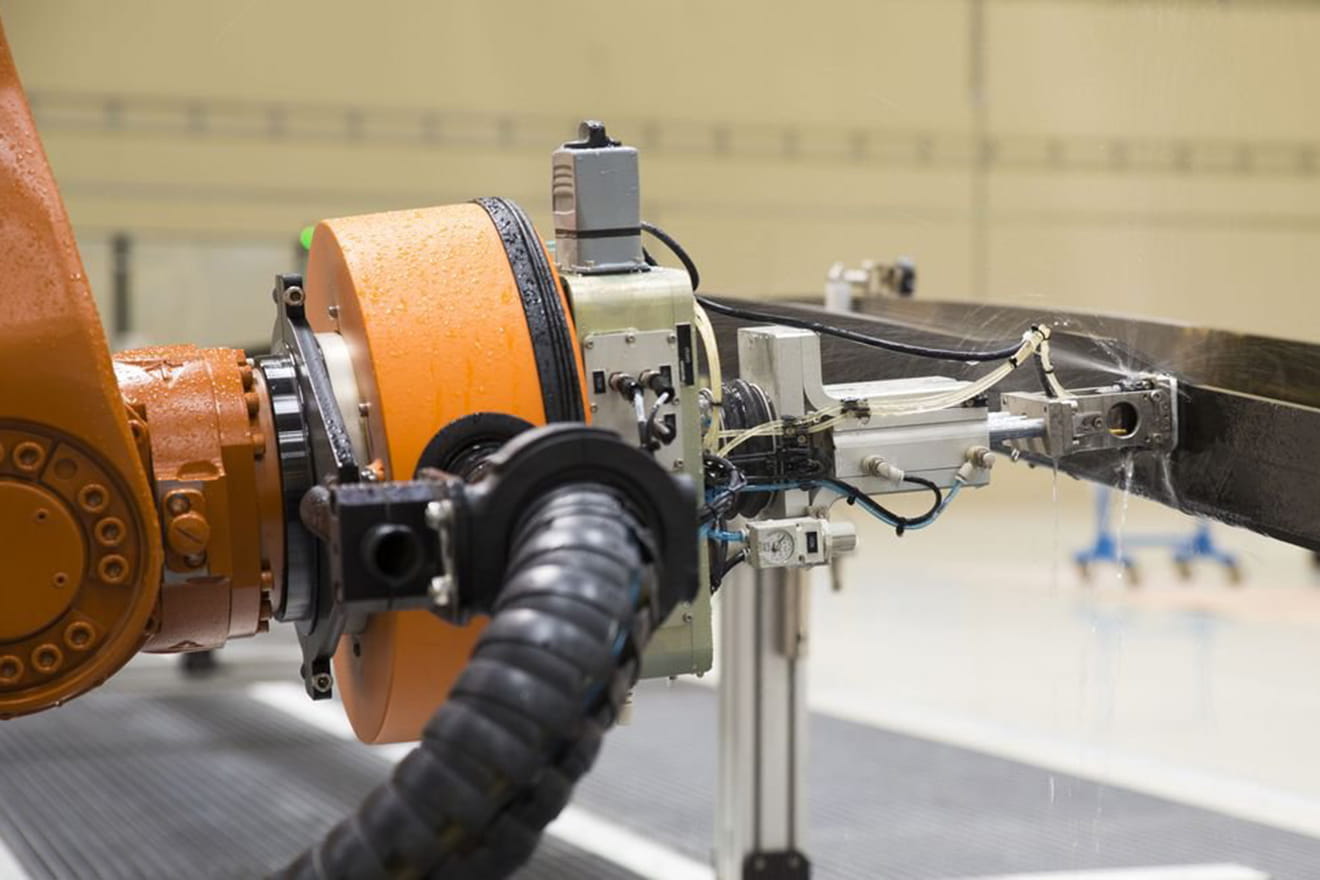

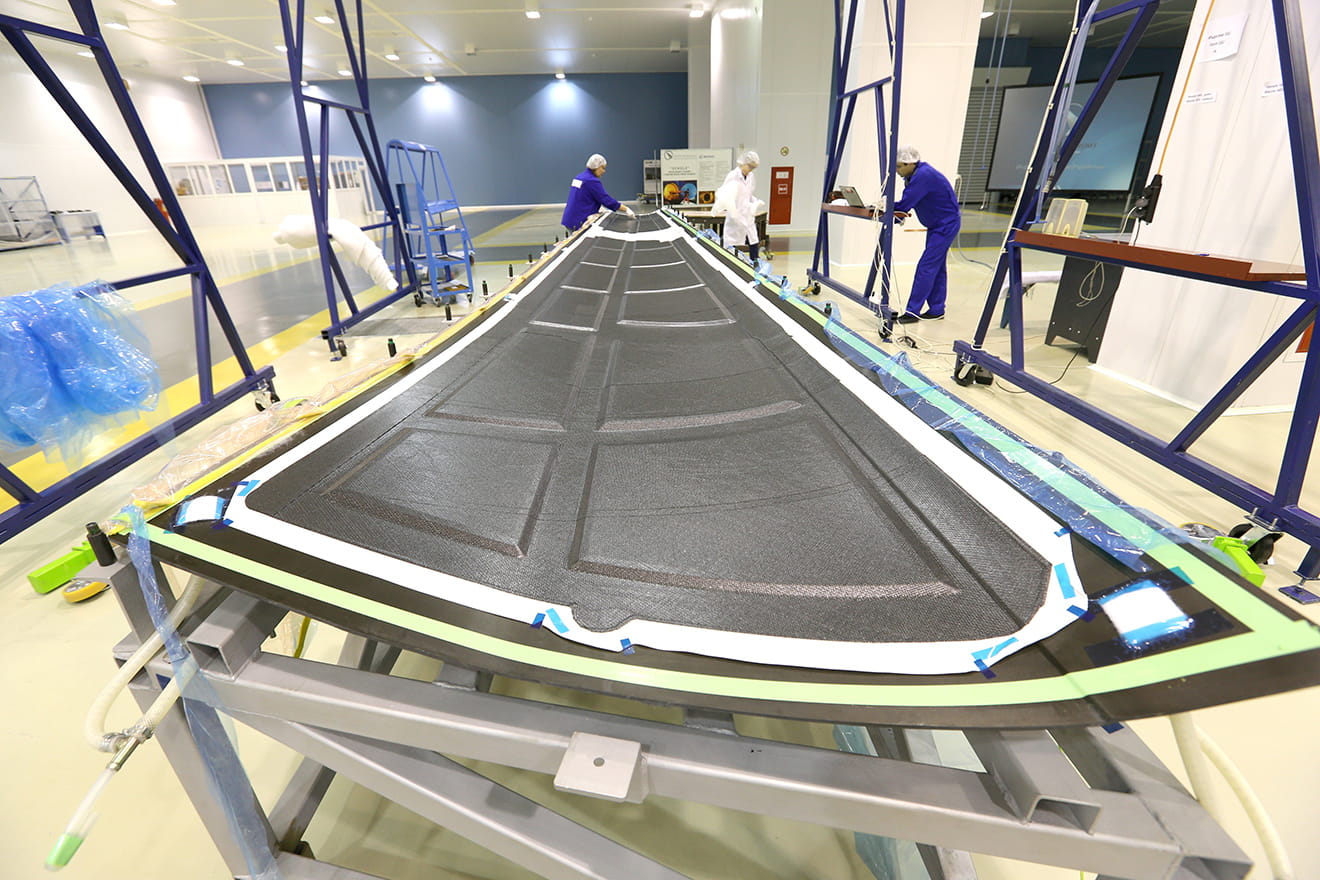

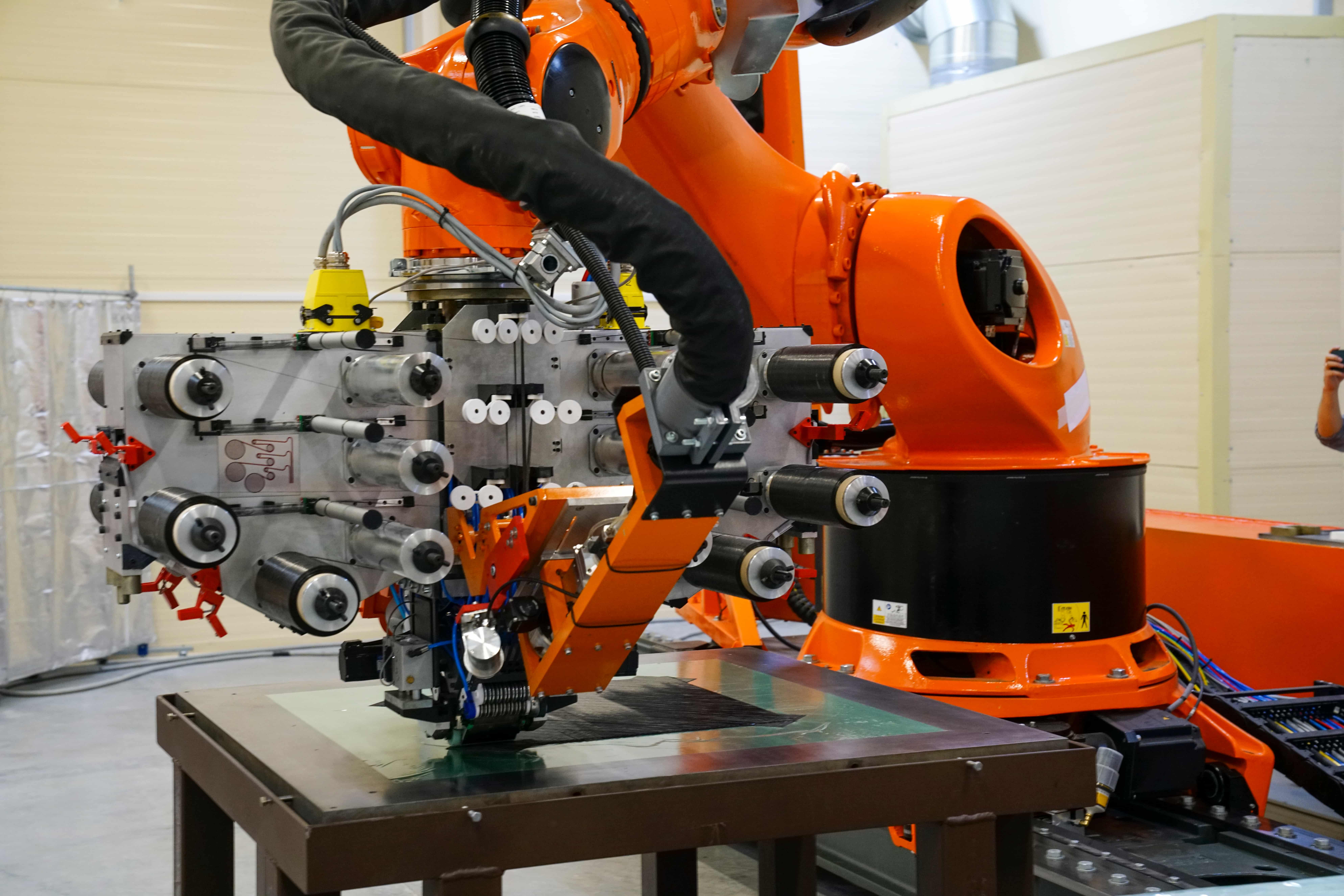

Ulyanovsk Plant

The plant specializes in the outerwing panels and the wing center section of the МС-21 jet airliner. It also performs the final assembly. The manufacturing procedure for polymer composite principal structural elements of the wing box (panels and spars) is based on the use of a unique infusion technology developed by local specialists. For the first time in the world aircraft industry, Russian engineers and other specialists have laid the groundwork for manufacture of large monolithic aircraft structures made of composite materials.

Kazan Factory

Production of composite units for the wing high-lift system, the tail, and composite components of the leading-edge and the trailing edge of MC-21 wing by prepreg autoclave casting.

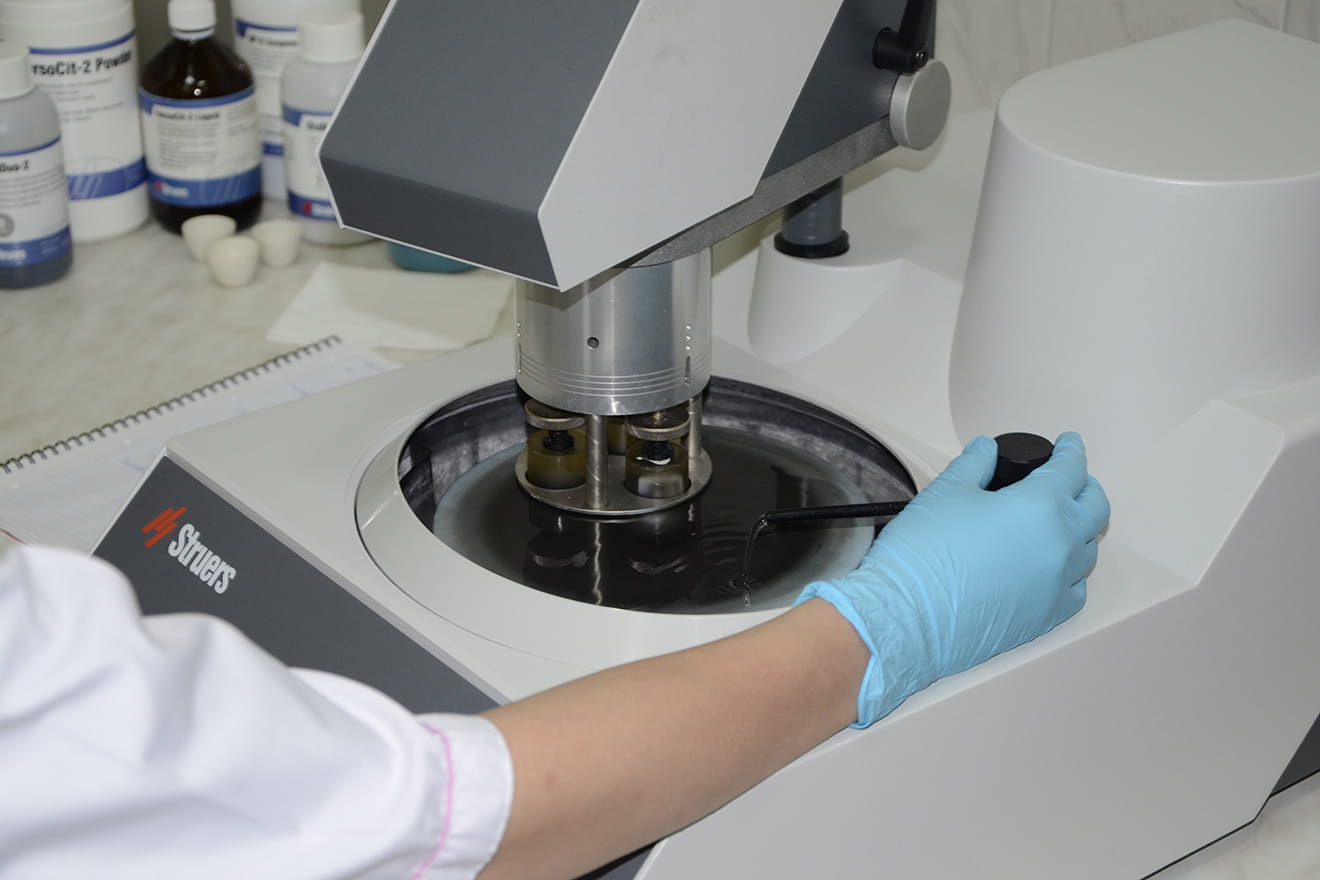

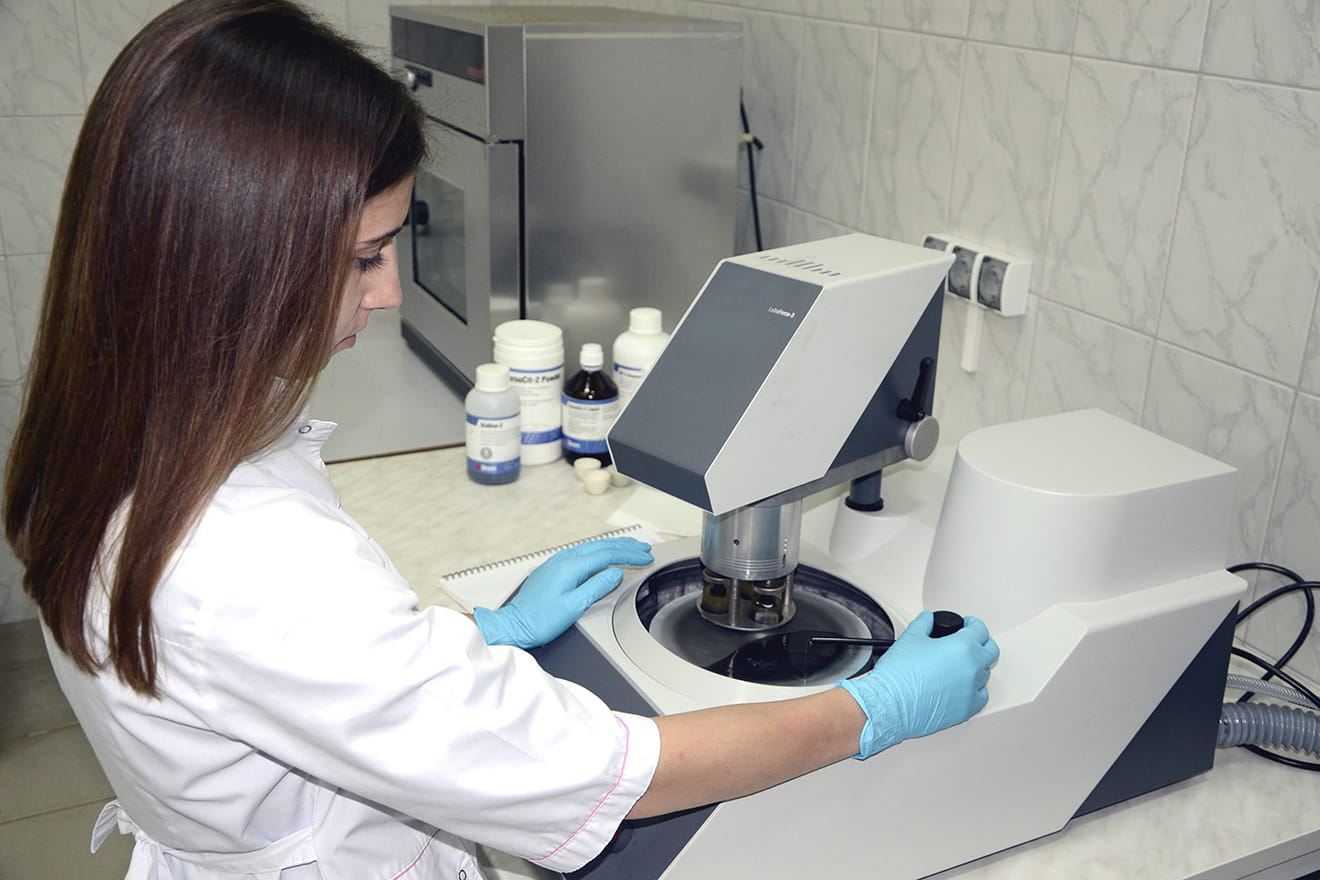

Technology Laboratory

In 2011, to implement the project, PCM technology and structures development laboratory was formed in the Moscow office of AeroComposit. Establishment of the laboratory was dictated by the polymer composite research needs, as well as by the need to develop new infusion technology.

In 2020, AeroComposit was incorporated into now Yakovlev PJSC as part of consolidation of the main scientific and production facilities of the civil aircraft industry.